What is Dormer Pramet CTW™ technology?

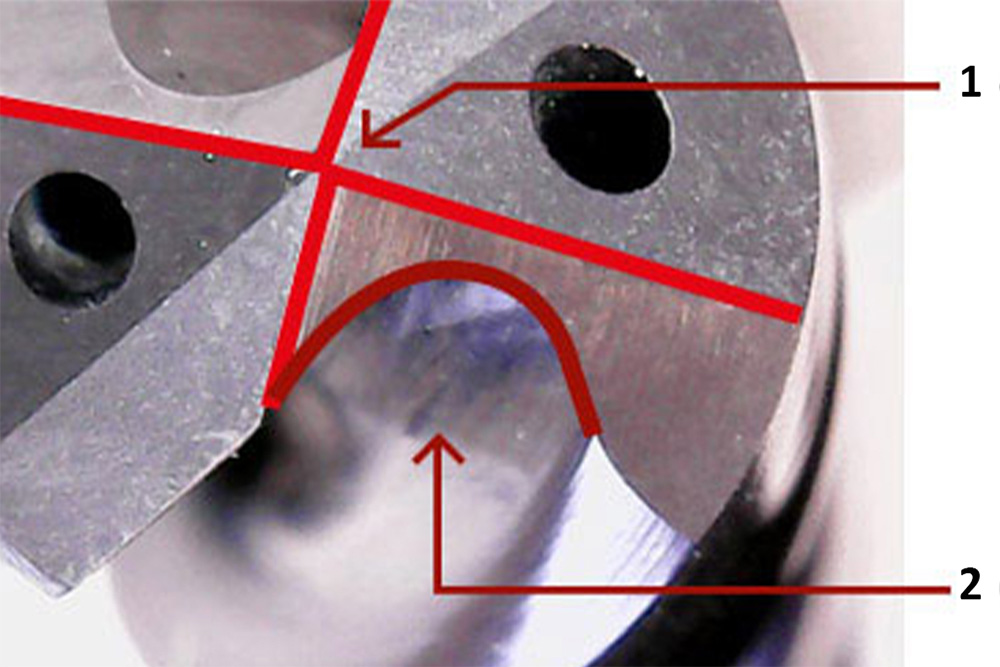

CTW stands for Continuously Thinned Web. By this it is meant that the core of the drill, from tip to shank, is constructed so that it is not necessary to provide the drill tip with a taper. Regrinding the clearance surface is sufficient. Since the core of the drill has the same thickness over its entire length, the geometry is more reproducible. With a normal core, the core of the drill gets thicker as the drill gets shorter. As a result, the point has to be ground in deeper and deeper so that the drilling pressure does not increase too much. A thicker core results in a longer cross-cut edge, which determines the force (drilling pressure) required to penetrate the material. The advantage of applying core thinning in the production of the drill is that the symmetry of the drill tip, and thus the drilling accuracy, is better maintained.

1: 4-LEVEL POINT, SPLITPOINT

2: CTW CHIP GROOVE CONTRUCTION

This technology developed by Dormer is now being applied to the solid carbide drills, so that the Force X and Force M drills contribute to the sustainable use of the raw materials needed for the production of carbide. Resharpening becomes much easier and therefore cheaper.

Our solid carbide drills only perform optimally if they are clamped in a high-accuracy recording. Therefore, the shaft is manufactured in accordance with DIN 6535 HA, i.e. a cylindrical unit shaft in H6 tolerance. It is especially suitable for the crimp holder or hydraulic tensioner. Of course, it can also be incorporated into a collet chuck, but in that case we recommend a precision collet chuck (with increased concentricity).

If only weldon holders are available, grinding a chuck on the drill is an option. However, this can negatively affect the accuracy and tool life of the drill at high speeds.

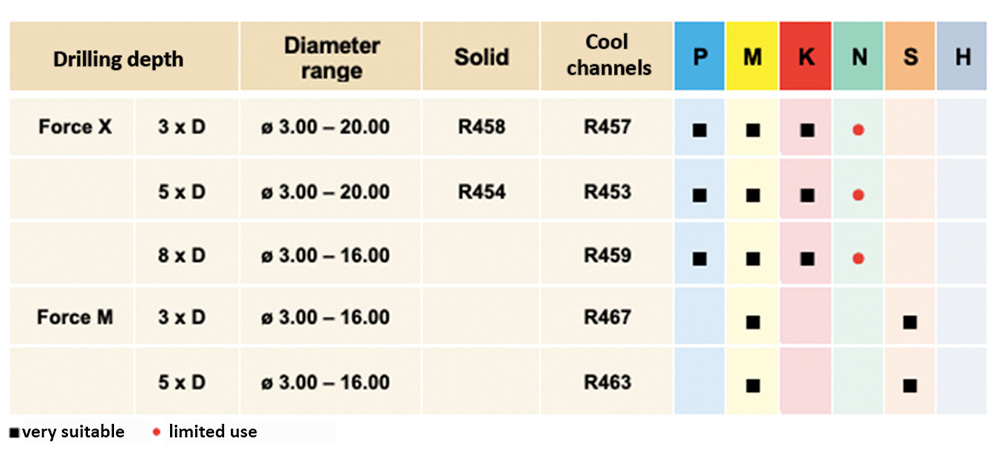

Usability of the solid carbide drills from Dormer Pramet

The Force X drills are designed for general purpose applications in steel, alloy steel, stainless steels and cast iron. The Force M drills have been specifically developed for stainless steels and titanium alloys.

Contact us for more info around the product and let us help your company to find the best solution for better effective & efficient production.

T +62 853 5370 8097

F +62 22 603 1487